Coady Introduction The surface quality of continuously galvanized coatings has improved significantly in recent years, enabling these coatings to replace electro-galvanized (EG) coatings in applications of exposed automotive body panels. To produce high quality zinc-coated strip, galvanizers need to improve quality control of the incoming strip as well as the continuous galvanizing process.

The recent introduction of high strength steels makes the production of galvanized coatings for applications such as exposed autobody panels even more challenging.

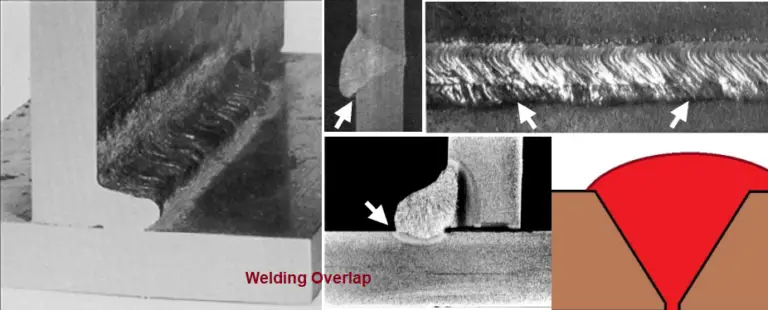

Studies indicate that poor substrate surface quality, insufficient strip cleaning, mechanical damage to the substrate surface due to handling, and inadequate process control are the main causes of coating defects. Coady Cominco Ltd., Product Technology Centre, Mississauga, Ontario, CanadaĪbstract Although the science and technology of continuous galvanizing have improved significantly over the years, it is still a challenge to produce defect-free coatings.

0 kommentar(er)

0 kommentar(er)